About what we do...

We are excited to present our factory

USS-PANEL®

" Sustainable & Disaster Proof "

The backbone of the USS-PANEL ® TECH system Leed Certified is a lightweight pre-formed panel, which makes the system suited to rapid and cost-effective construction.

Buildings are safe, sustainable, non-combustible and strong enough to resist hurricane, tornado-force winds, earthquakes, mold or mildew, bug and rat resistant.

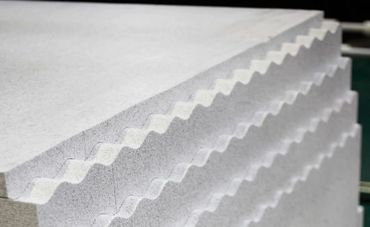

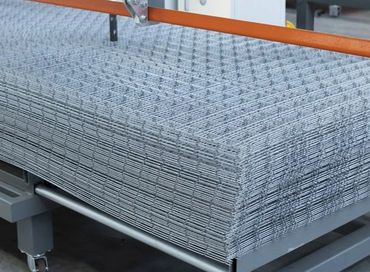

Our Patented & Trademarked Product - is made of a polystyrene foam core sandwiched between two layers of galvanized steel wire mesh. The lightweight panels can be easily handled by workers w/o major equipment. The foam core makes this possible, but the foam itself would not be very durable if left exposed, so a layer of concrete is applied to the panels (by shotcrete or hopper projected) to add strength (4000 - 5000 psi) and create long term durability.

Foam panels provide another design benefit too, because foam is much less dense than the layer of concrete, the structure’s dead weight is reduced and smaller footings are needed, which saves on the overall costs of the buildting.

Taller buildings incorporate a concrete skeleton or steel frame, and the repeating bays lend themselves to the prefabricated panel construction.

The factory manufactures and supplies sandwiched structural panels and other foam block elements used in numerous architectural and construction applications.

Our foam panels are used for any type of dwelling whether residential, commercial, industrial, retaining walls, weight reduction for utilities, building foundations, bridge abutments, side hill, weight reduction for high-rise buildings.

The applications are endless.

Photo Gallery

Finished Product

Contact Us

USS-PANEL® TECHNOLOGIES LLC.

Copyright © 2011-2022 USS-PANEL© TECHNOLOGIES LLC. - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.